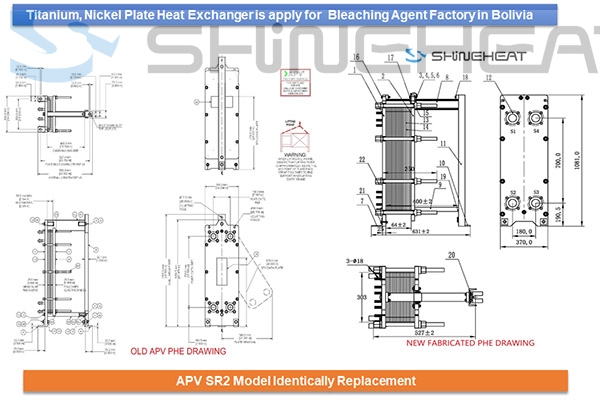

SHINEHEAT Plate Heat Exchanger Apply for Bleaching Agent Factory in Bolivia

Nickel and Titanium Plate Heat Exchanger Apply for Bleaching Agent Factory in Bolivia

DETAIL

3 Sets of Nickel 201 and Titanium PHEs Applied in Bleaching Agent Factory in Bolivia

In bleach production processing, the plate heat exchangers are applied to cool and heat caustic soda and sodium hypochlorite solution to control the processing temperature and recycle heat. Due to the corrosive of working mediums, special type materials (nickel plate used in the working condition of caustic soda, titanium plate for working condition of sodium hypochlorite) need to be adopted. Because of the special material, heat exchanger production and processing technology is more difficult than that of normal material plate heat exchangers.

One of Shineheat's clients in Bolivia is a bleach manufacturer. At the end of May, the client placed an order of 1 set of 30% sodium hydroxide solution cooler with plates made of Nickel 201, and 2 sets of 10% sodium hypochlorite solution coolers made of Titanium and 60 pcs of EPDM gasket accessories. Old APV PHE drawing was sent to us from the client. They expected that we could maximum copy the old heat exchanger dimensions and performance. We issued the drawings and produced the plate replacement according to the customer's requirements perfectly. The 3 sets of replacement plate heat exchangers passed the inspection and were delivered to the customer at middle of July.