SHINEHEAT PLATE HEAT EXCHANGER APPLY FOR CAUSTIC SODA COOLER

Shineheat offer a Plate heat exchanger as Caustic Soda Cooler at Chlor-alkali plant.

DETAIL

Shineheat plate heat exchanger apply for Caustic Soda Cooler

In Chlor-alkali chemical plant, the Caustic Soda Solution need to cool or thermal recycle during the production process. Plate and Gasket Heat Exchanger or Welded Plate and Frame Heat Exchanger play the important role during cooling or heat exchanging process.

In order to make qualified products, the Caustic Soda Solution need to reach specific temperature range. This job is definitely implemented by High efficient Plate type heat exchanger.

Now Shineheat offer a Plate heat exchanger as Caustic Soda Cooler at Chlor-alkali plant.

Following is design data sheet of plate heat exchanger.

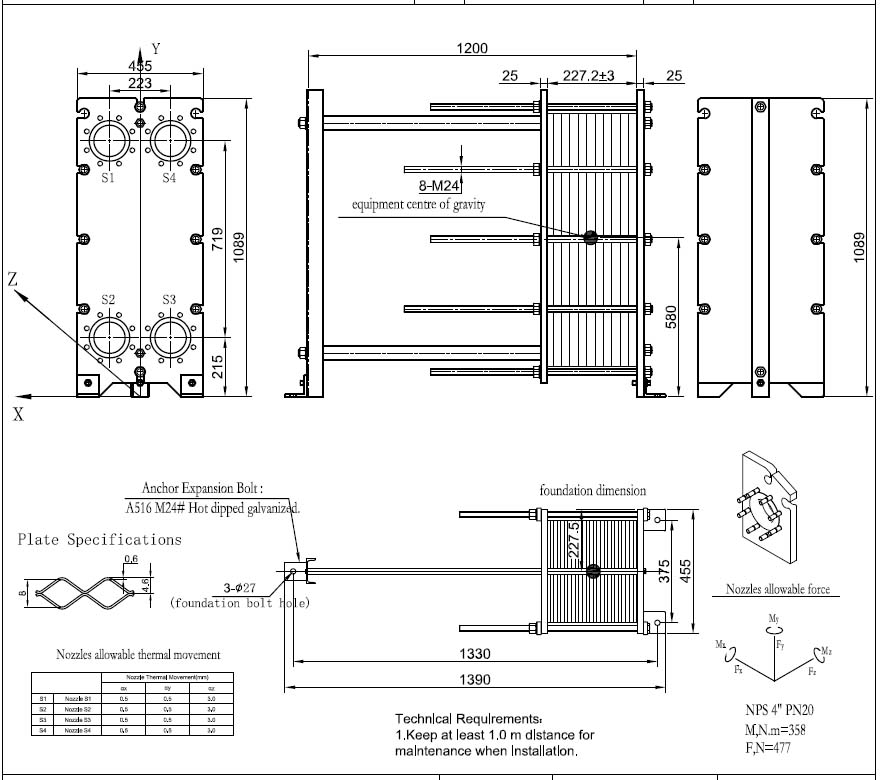

Model : AT100B/71/PN10/NICKEL/EPDM

Project: : NaOH Cooler

Item : Date : 2018/09/07

___________________________________________________________________________

Fluid 32.0% NaOH Water

Mass flow rate kg/h 15000 63600

Fluid Condensed/Vapourized kg/h 0.000 0.000

Inlet temperature ¡ãC 80.0 32.0

Outlet temperature(vapor/liquid) ¡ãC 40.0 40.0

Operating pressure(In/Out) bara /

Pressure drop(Perm/Calc) kPa 100/1.53 50.0/33.1

Velocity Connection(In/Out) m/s 0.406/0.398 2.26/2.27

Heat exchanged kW 590.5

Heat transfer area m2 17.75

O.H.T.C clean conditions W/(m2*K) 1866

O.H.T.C service W/(m2*K) 1672

Additional Excess Surface % 11.6

Mean Temperature Difference K 19.9

Relative direction of the fluids Countercurrent

No. of plates 71

No. of effective plates 69

Number of passes 1 1

Extension capacity 20

Plate Material: 0.6mm Nickel 201 Plate

Gasket Material: EPDM

In view of High Corrosive feature of Caustic Soda, we use 0.6mm Nickel 201 material sheet as Plates. The Nickel 201 raw material comes from Nippon of Japan, the Ni Composition is 99.5%. Furthermore, Shineheat’s procurement is all Positive Allowance in Nickel plate thickness, generally in 0.65mm before pressing. It is contribute longer service life for Shineheat Plate Heat Exchanger.

By many years’ supplying experience in Chlor-alkali industry, we design optimal model of plate heat exchanger by both thermal efficiency, pressure drop and size economical, also take future capacity expansion into consideration, so you will find our enough length in Carrying and Guarding Bar of plate heat exchanger.

The Design Drawing for Welded Plate and Frame Heat Exchanger

The Plate Heat Exchanger Photos

At Site, New plate heat exchanger installed and operated very successfully, the delivery time is Sept 2017, up to now it is running on good condition and performance.