Spiral Plate Heat Exchanger Application in Chemical Plant

In chemical plant, there are many applications need Spiral Heat Exchanger, especially for waste water heating recycle applications

DETAIL

In chemical plant of Formosa group, there are many applications need Spiral Heat Exchanger, especially for waste water heating recycle applications.

In view of waste water contain a lot of dirties, so wide gap spiral flow is idea solution for the Job. Currently Alfa Laval Spiral Heat Exchangers are on operating at site.

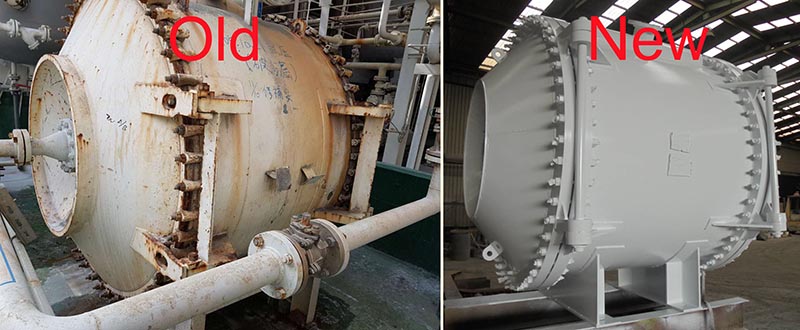

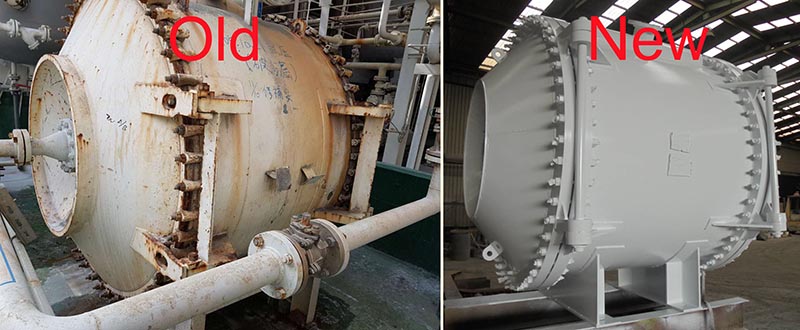

However the leakages are occasionally happened and no service from supplier. So Formosa decide to gradually replace the exist Spiral heat exchangers by the new units which provided by the most qualified supplier.

After comprehensive investigation and evaluation, Shineheat finally award this bidding to provide First 250 Square Meters Spiral heat exchanger to the project.

The capacity per unit is big, and Formasa ask dismountable in both side for regular maintenance and clean.

Then the problem is coming, Each Flat Cover is nearly 3000kg, how could solve the problem for moving such heavy Flat Cover in possible routine way without heavy lifting?

Based on many times trying and testing, Shineheat team find a mechanical solution for it at very reasonable cost.

Adopting mechanical Rotational device, then could open the Flat Cover without dismount it. The strong Rotational column could ho ld the Flat Cover when it open.

ld the Flat Cover when it open.

Another challenge is 1:1 fabrication against the exist unit, even for connection locations and feet anchors detail. The Formasa requests replace the old unit without any modification in foundation and pipeline arrangement. if it could be accomplished, then other old units also could be consider to replacement.

Definitely all the practical size are in accurately measurements!

For the whole unit of Spiral heat exchanger, the net weight is about 15000kg. So we also need to consider a special and reliable way to packing and transport. so we use special soft packing material to protect exterior of unit and also save transportation space.

In view of waste water contain a lot of dirties, so wide gap spiral flow is idea solution for the Job. Currently Alfa Laval Spiral Heat Exchangers are on operating at site.

However the leakages are occasionally happened and no service from supplier. So Formosa decide to gradually replace the exist Spiral heat exchangers by the new units which provided by the most qualified supplier.

After comprehensive investigation and evaluation, Shineheat finally award this bidding to provide First 250 Square Meters Spiral heat exchanger to the project.

The capacity per unit is big, and Formasa ask dismountable in both side for regular maintenance and clean.

Then the problem is coming, Each Flat Cover is nearly 3000kg, how could solve the problem for moving such heavy Flat Cover in possible routine way without heavy lifting?

Based on many times trying and testing, Shineheat team find a mechanical solution for it at very reasonable cost.

Adopting mechanical Rotational device, then could open the Flat Cover without dismount it. The strong Rotational column could ho

ld the Flat Cover when it open.

ld the Flat Cover when it open.Another challenge is 1:1 fabrication against the exist unit, even for connection locations and feet anchors detail. The Formasa requests replace the old unit without any modification in foundation and pipeline arrangement. if it could be accomplished, then other old units also could be consider to replacement.

Definitely all the practical size are in accurately measurements!

For the whole unit of Spiral heat exchanger, the net weight is about 15000kg. So we also need to consider a special and reliable way to packing and transport. so we use special soft packing material to protect exterior of unit and also save transportation space.