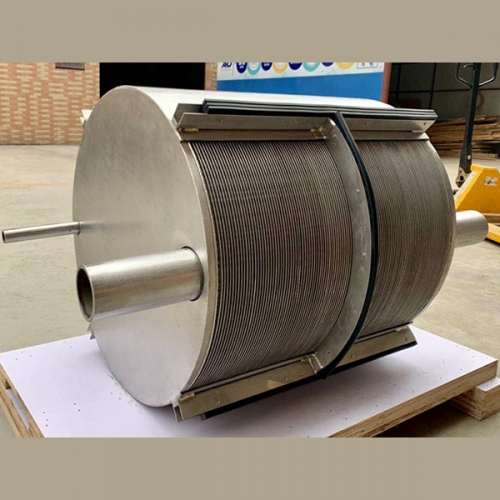

Welded Plates Pack for Plate and Shell Heat Exchanger

Customized Design and Manufacture for Welded Plates Pack or Core for Plate and Shell Heat Exchanger

DETAIL

Project Background

ISO VG 22 need to cooling from 70 °C to 35 °C,end user don’t want to use plate and frame heat exchanger because they need to change the gasket every half year.

Shineheat provide the Plate and Shell Heat Exchanger solution instead of the Plate Heat Exchanger.

In view of local regulations, the pressure vessl products need to be finished at local supplier, so we provide proposal as following,

Welded Plates Pack, Internal Sealing Accessories of plate and shell heat exchanger is provided by Shineheat;

Shell and Foundation Part is provided by local parnter.

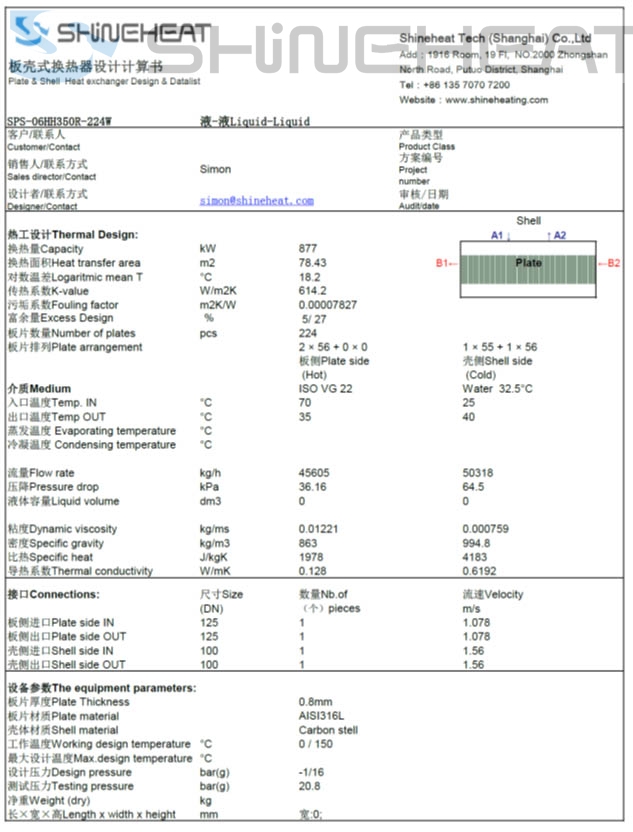

Slection Specifications

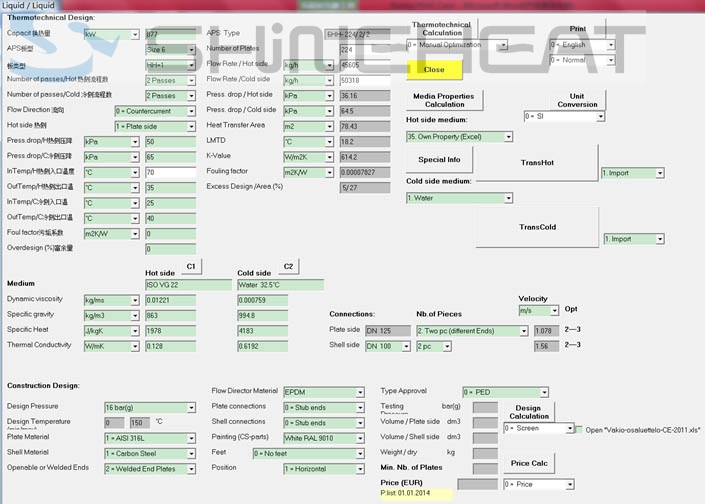

HOT SIDE: ISO VG 22

Inlet and Outlet temperature is 70-35 °C

Pressure Drop < 70kpa

COLD SIDE: Water

Inlet and Outlet temperature is 25-40 °C

Pressure Drop < 50kpa

Heat Load 877 kw

Shineheat Selection Software Slection

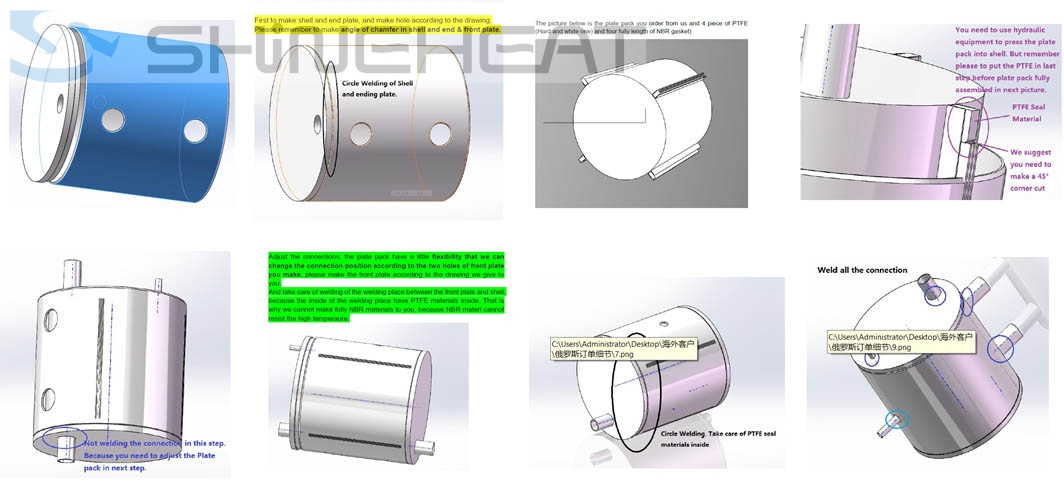

In view of the Plate side is two pass arrangement design, so it is a little challenge to coordinate each part's work, especially to assemble welded plates pack into the Shell.

There are some key conerns should be follow in order to perfect coupling and assembling.

* Welding Procedure of Shell, Start Round Plate and End Round Plate

* Assemble Procedure of Internal Sealing Accessories

* Connections Welding Procedure of Plate and Shell Heat Exchanger

Shineheat provide complete assembly and coupling Instruction Manual to customer

PHOTO FOR FINAL ASSEMBLY PRODUCTION

Important Note, The internal sealing material is NBR rubble in view process fluid is Lube Oil, However, the user want to use Hight temperature team to clean Shell Side in regular service time. Regular NBR could possible broken by Steam, how we handle this problem properly?

We have Ideal Solution for it, please contact us for more detail!