Description

Brazed Plate Heat Exchange Introduction

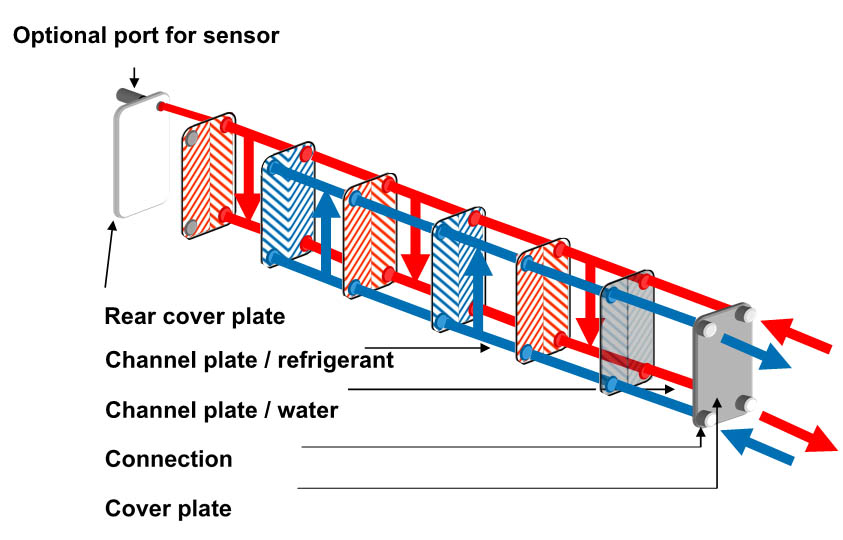

The principal Brazed Heat Exchanger design is constructed using a series of thin corrugated Stainless Steel plates that are brazed together with Copper or Nickel in a vacuum furnace.

Providing the ability to remove and transfer heat from one medium to another, our brazed plate heat exchangers are a cost-saving alternative to conventional evaporators and condensers used for all types of commercial and industrial refrigeration, cooling, air conditioning and oil cooler applications.

Less space and weight, wide range of sizes and cooling capacities, high heat transfer surface, great versatility, available for high-viscosity fluids and low energy consumption are just a few of the many items on its benefits list.

Brazed Plate Heat Exchanger Features

- Compact design Low fouling

- High corrosion resistance

- Easy to service

- NPT or BSP connection type of water/brine side

Approvals CE certificate according to (PED) 97/23/EC UL RoHS

Brazed Plate Heat Exchanger Technical data

- Stainless steel AISI 316L,304L,SMO 254

- Copper or nickel brazing

- Heat load between to 1 KW and 550 KW

- Tempmin -195o C, Tempmax +200o C

- Design pressure up to 45 bar

- connection: threaded and welded

- double circuits and modular applications

- R134a, R22, R410A, Water, …CO2

- Oil, Air dryer and others

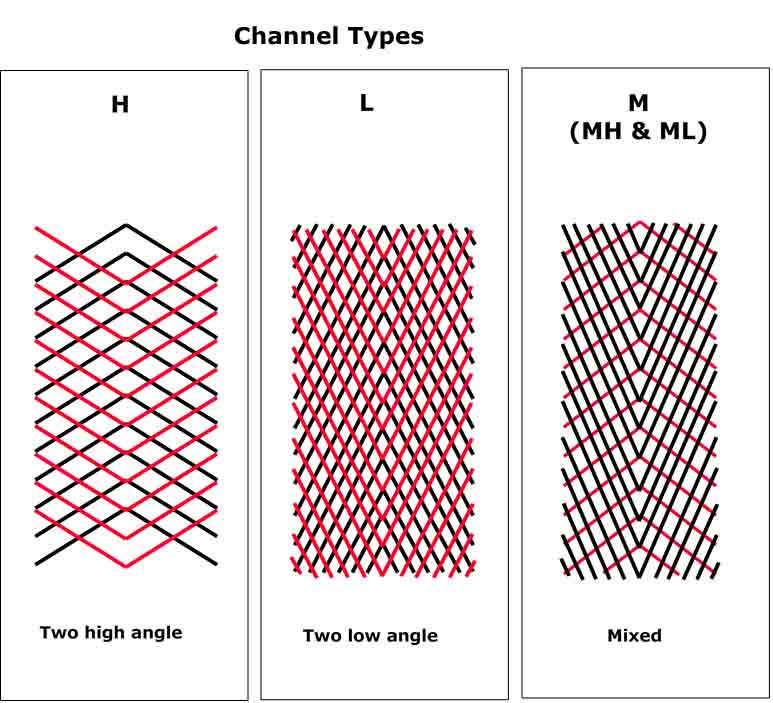

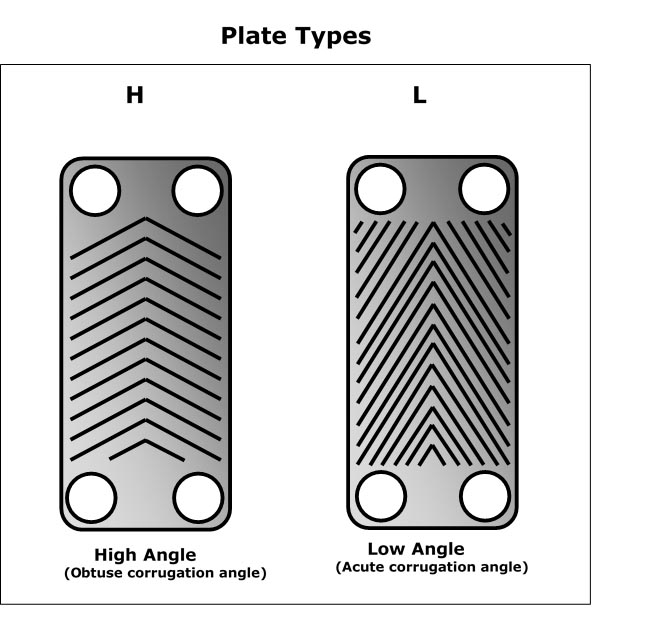

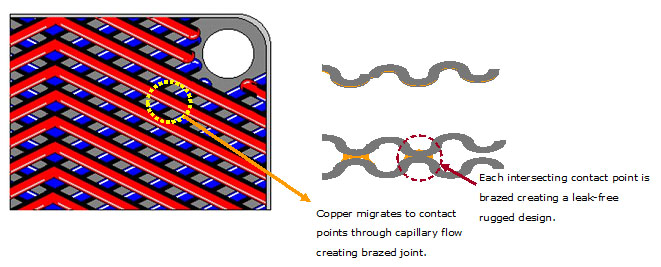

Plate angle and pressing depth influence both the pressure drop and thermal performance of the plate. Plates can be combined and mixed for optimum performance.

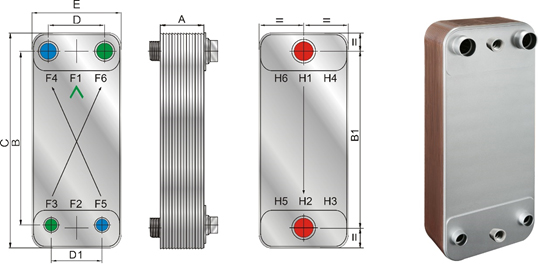

Principal Brazed Plate Heat Exchanger

Plate Design Features

Contact points

- Thermal length and width

- Port locations

- Pressing depth

- Distribution areas

- Press pattern & angles

- Mitigating “dead zones”

- Brazed joint design

- Creating a strong pressure vessel

- Every second plate is turned 180°

- Chevrons create the contact points

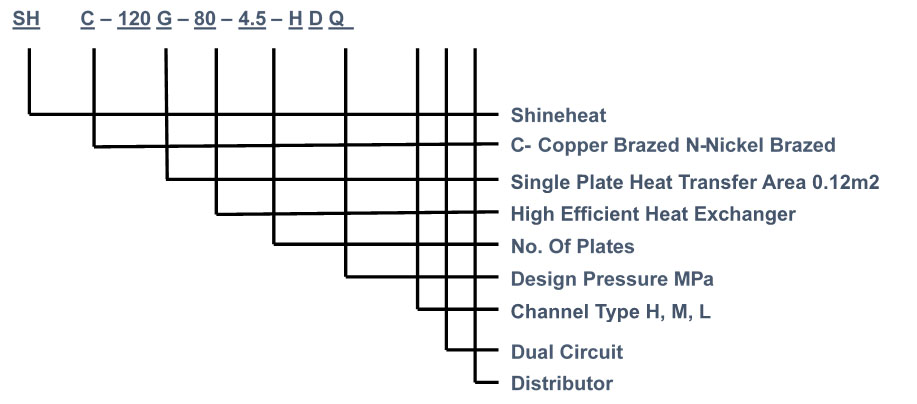

The Description of Model Name

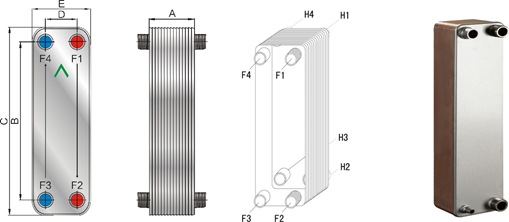

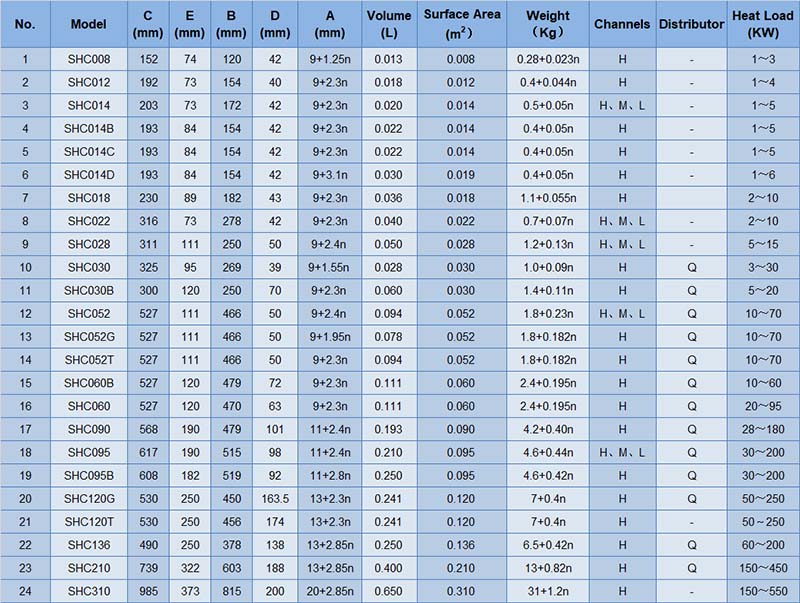

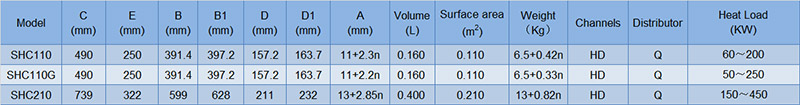

Brazed Plate Heat Exchanger Dimension Data

RELATED PRODUCTS

REVIEW