Description

Spiral Heat Exchangers are the ideal solution for "Heavy Duty" Heat Exchanger, in extremely dirty and fouling process duties. The self-cleaning features inherent in the design, give unparalleled uptime between service intervals and quick and easy service turn-around.

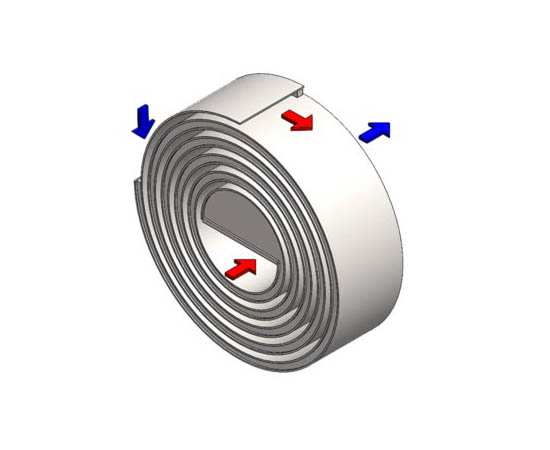

Design Structure for Spiral Heat Exchanger

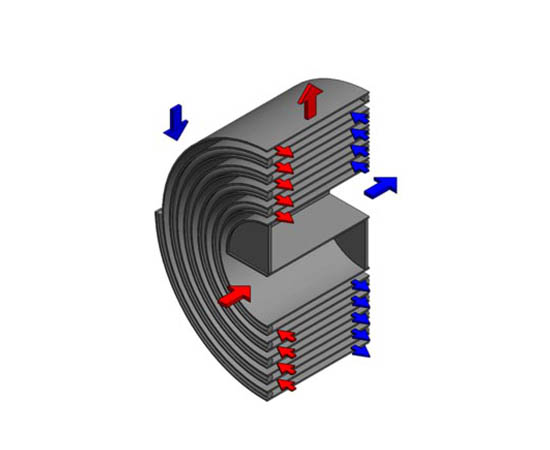

The spiral plate heat exchanger is made by rolling two long metal plates around a center core to form two concentric spiral flow passages, one for each fluid. The plate edges are welded shut so that each fluid stays within its own passage and there is no flow bypassing or intermixing. Channel plate width and spacing (gap between plates) are optimized for the specified duty, maximum heat transfer, and ease of access. The plate gap is maintained by welded spacer studs although some designs do not require them.

Due to its inherent circular design and large surface area to volume ratio, the spiral heat exchanger offers unique advantages over other types of heat exchangers like the shell and tube.

Features and Advantages for Spiral Heat Exchanger

High Thermal Efficiency

Single and long curving flow passages with a uniform rectangular cross-section ensure superior flow distribution, intense turbulence, and high heat transfer coefficients (50-100% greater than shell & tubes).

Self-Cleaning Passages

The spiral's single-flow passages induce high shear rates that scrub away deposits as they form. This self-cleaning effect reduces fouling and makes spiral heat exchangers ideal for handling tough fluids such as process slurries, sludge, and media with suspended solids or fibers.

Countercurrent or Co-current

Spiral heat exchangers normally operate in true countercurrent flow for close approaches and temperature crosses. Occasionally a co-current flow design has major benefits, especially in cooling or heating fluids prone to gelation, burn-on, freezing or similar skin temperature related fouling.

Small Footprint & Easy Access

The spiral heat exchanger is compact and requires minimal space for installation and servicing. Removable covers provide easy access to interior heat transfer surfaces for field inspections, routine maintenance, or manual cleaning if required.

Supply Range for Sprial Heat Exchanger

| Min~Max | |

| Heat Transfer Area (m2) | 5~600 |

| Design Temperature (℃) | -50~400 |

| Design Pressure (Bar) | Full Vacuum~20 |

| Application Code | ASME, KS, JIS, BS, PED |

| Spiral Plate Material | SS304, SS316L, 254SMO Nickel Alloy, C-276 , Titanium |

Typical Spiral Configurations

- Spiral Flow Both Sides

* Steam heating or vapor condensing

* Suitable condenser at pressures above atmospheric

* Countercurrent or co-current flow

* Best for crossing or close approach temperatures

* Self-cleaning effect in both spiral passages

* Ideal for handling suspensions, slurries & sludge

* Removable covers for independent & easy access

- One Side in Cross Flow, One Side in Spiral Flow

* Vapor in annular cross flow

* Cooling medium in spiral flow

* Extremely low vapor side pressure drop

* Large flow cross-section for large vapor volumes

* Short height of condensing section

* Suitable in liquid to liquid duty with large flow imbalance

- Combined Cross - Spiral Flow

* Optimal for mixed vapors with inert gases

* Built-in internal subcooling section

* Suitable for low to moderate operating pressures

* Combines features of Types 1 & 2

* Excellent steam heater of viscous fluids & slurries in horizontal direction

Key Application Industries

PVC slurries

Particle laden/fiberous media in Ethanol, Textiles, Pulp and Paper etc.

Erosive slurries Metal extraction and Processing

Hydrocarbon Processing

Viscous fluids such as Heavy Oils and Oil Extraction

Distillation, Condensation and Reboilers

Vegetable Oil Deodorizing

Non-Newtonian fluids

Sewage Sludge and Waste Water

Spiral Heat Exchangers & Renewable Energy

Spiral heat exchangers are also used in green anaerobic digestion processes that produce biogas from organic wastes such as livestock manure, food by-products, fats, oils, and grease.

Biogas, a mixture of methane and CO2, is a renewable energy that can be combusted to generate heat and electricity. After dewatering, the remaining pathogen-free biosolids can be used for soil conditioning as fertilizer.

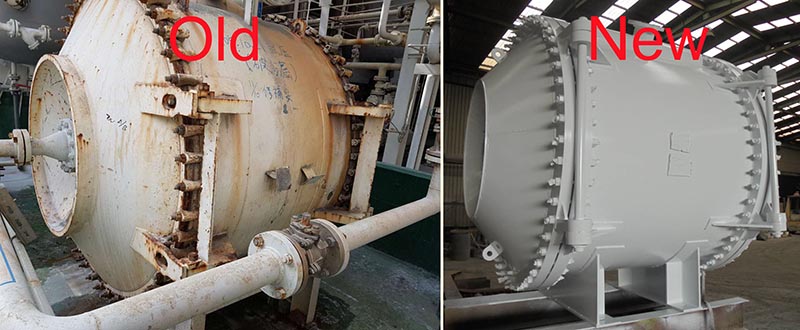

Service and Replacement Manufacturing

Customized design and manufacturing is available from us. The old equipment could be replaced by brand new by which is 100% identical and same in Size and Thermal Performance.

End user even need not to do extra pipeline and foundation Job.

RELATED PRODUCTS

REVIEW